Pharmaceutical Aerosols

Capillary-Based Dry Powder Inhaler

Improving the delivery of pharmaceutical aerosols

Dry Powder Inhalers (DPIs) are used for generating and delivering pharmaceutical aerosols from powders. These DPIs store individual doses in containment units known as capsules or blisters, which are pierced by a needle that is then retracted when the user pushes a button. While these capsules are easy to fill and protect each dose, piercing the capsule often requires an additional step in most devices prior to inhalation. VCU researchers have developed a device which uses hollow capillary tubes to simplify the process of using DPIs, while improving powder dispersion and emptying.

The technology

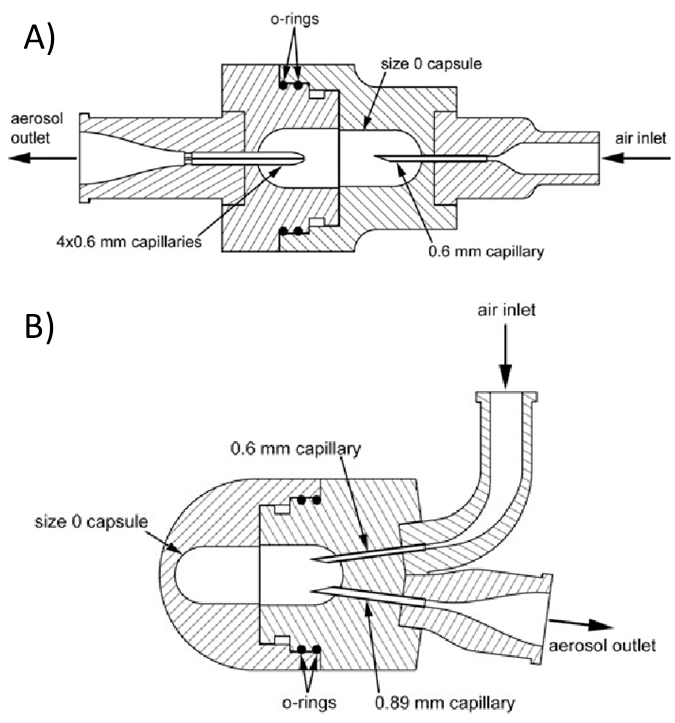

The proposed device replaces traditional needles with sharpened hollow capillary tubes (capillaries), which eliminates an extra step of engaging the device. The capillaries remain fixed within the capsule or blister during actuation which helps to form an inlet high speed jet and outlet filtering mechanism. This prevents large particles from exiting and thereby produces a fine aerosol. The flow pathway of the device is also designed to work with positive pressure sources such as a syringe, airbag, or compressed air supply. There are currently two iterations of the device, one where the capsule inlet and outlet capillaries pierce the capsule on opposite sides, and one where they pierce the capsule on the same side (Figure 1).

Figure 1. A) Design where capillaries pierce the capsule from opposite ends to create the airflow pathway; B) Design where capillaries pierce the capsule from the same end to create the airflow pathway