Pharmaceutical Production Methods

Palladium Catalysts for C-H Reactions

Improved methods for API synthesis

The process of synthesizing Active Pharmaceutical Ingredients (APIs) often involves C-H activation reactions as they are the most atom-economical route to build complexity into small molecules. Current methods to produce C-H activation reactions use soluble, homogeneous palladium catalysts. While effective, this methodology does have some limitations, such as the need to remove residual palladium through purification steps which can be costly to pharmaceutical companies.

The technology

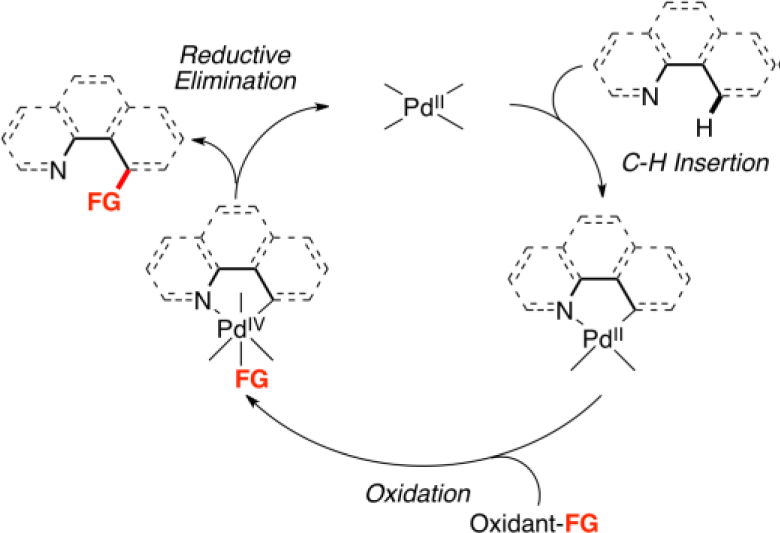

Researchers at VCU have developed a novel method of incorporating heterogeneous palladium catalysts in C-H activation reactions. Compared to conventional processes, toxicity is significantly decreased using this method due to a high removal of residual palladium via filtration (contamination < 250ppb). This method also allows for the conversion of C-H to the following: C-O, C-Cl/Br/I, C-C, C-N, C-F and C-CF3. Furthermore, the catalyst can be recycled (>16 times) for future reactions and has a high turnover frequency leading to improved reaction kinetics.

Figure 1. Pd(II)/Pd(IV) Catalytic Cycle for N-Chelation directed C−H Activation Reactions