Wastewater treatment

Heavy metal adsorbent

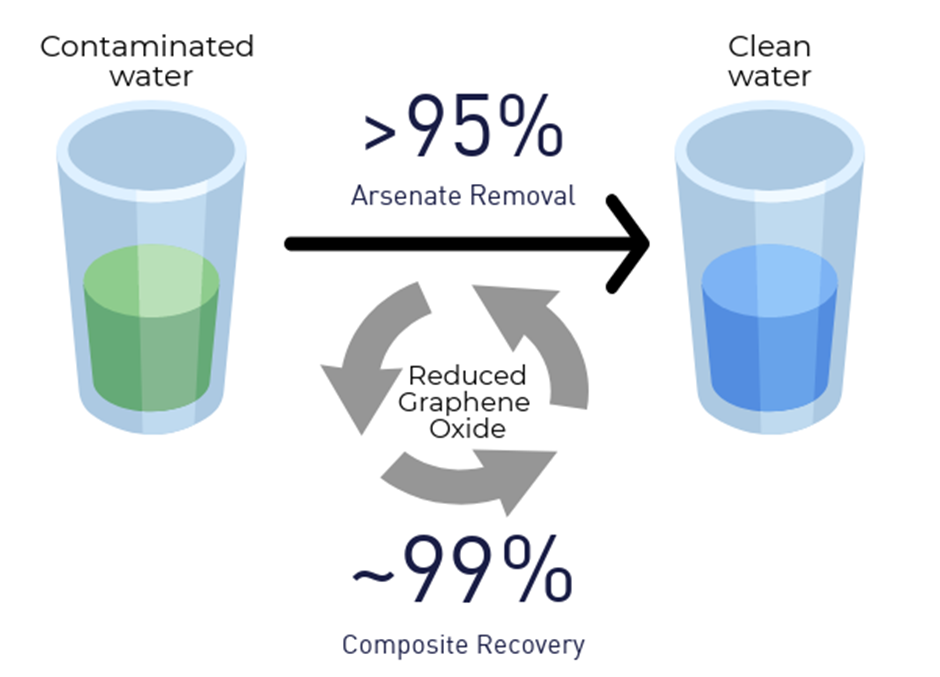

Process for graphene-based water treatment

VCU researchers have developed a simplified method of producing reduced graphene oxide and iron oxide nanocomposite for the removal of heavy metals from wastewater. This composite has been shown to be a strong chelating agent and can also be easily produced in current chemical production practices. In addition to this technique being more efficient and cost effective than standard production methods, the materials can be recycled and reused due to their magnetic properties. This allows companies to significantly reduce the cost of heavy metal removal during wastewater treatment.

Arsenic and other heavy metal contaminants in water can lead to significant health issues, as well as structural damage over time. Current wastewater treatment industries utilize nanoparticles to adsorb and remove the heavy metals. Processes to produce these nano-particles or nano-sheets can be costly and difficult. VCU’s novel method allows for simpler construction of these materials, reducing the cost and difficulty of manufacturing. In addition, these efficient materials are magnetic allowing for recyclability and reusability.

The technology

The technology consists of graphene-based nanomaterials that are chemically modified to adsorb a variety of pollutants. When these materials are exposed to the contaminated water, the contaminants bind to them, allowing them to be sequestered and removed from the water along with the graphene-based nanomaterials. This process is capable of efficiently removing Arsenate, heavy metals, and Phosphate from wastewater. Due to the high chemical stability of these nanomaterials, recycling of the material extends the usability and efficiency of the treatment. VCU is seeking market insights on commercialization of this new nanoparticle production method. We welcome interest from potential partners and licensees.

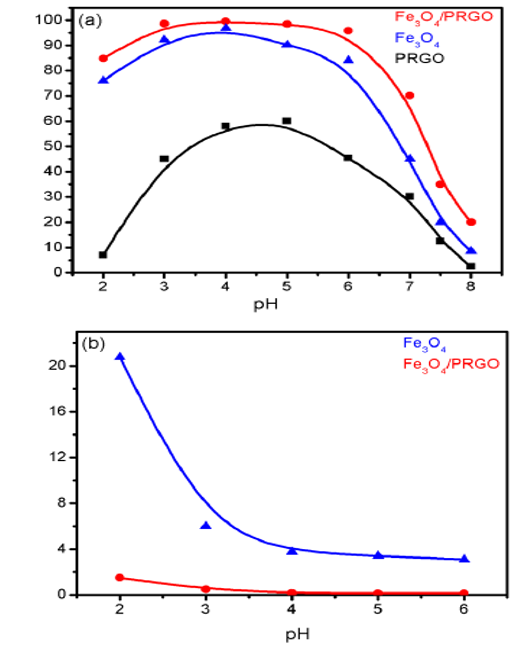

Figure 1: (a) Percent removal of Arsenic at varying pH. (b) Amount of Fe leeched from the material at varying pH