Solar Cell Materials

High-quality perovskite films

Low-temperature formation of perovskite films using supercritical CO2

Organic-inorganic perovskites are one of the most promising materials for the next generation of solid-state solar cells. Perovskite materials are the leading candidate for cost-effective renewable energy due to their record-breaking efficiencies, which approach 30%, and low-cost solution-based processing. Perovskite films are produced by depositing inorganic/organic precursors from solution onto a substrate followed by post-deposition processing to remove residual solvent and induce crystallization. Today, high annealing temperatures, usually above 100oC, are used to produce high-quality films; however, detrimental effects, such as the reduction of photovoltaic performances occur at these elevated temperatures. Using low annealing temperatures is currently impractical due to the significant amount of time needed for the material to fully crystallize. Thus, a method whereby high-quality perovskite films are produced rapidly at low annealing temperatures is needed and would represent a major advancement in perovskite solar cell technology.

The technology

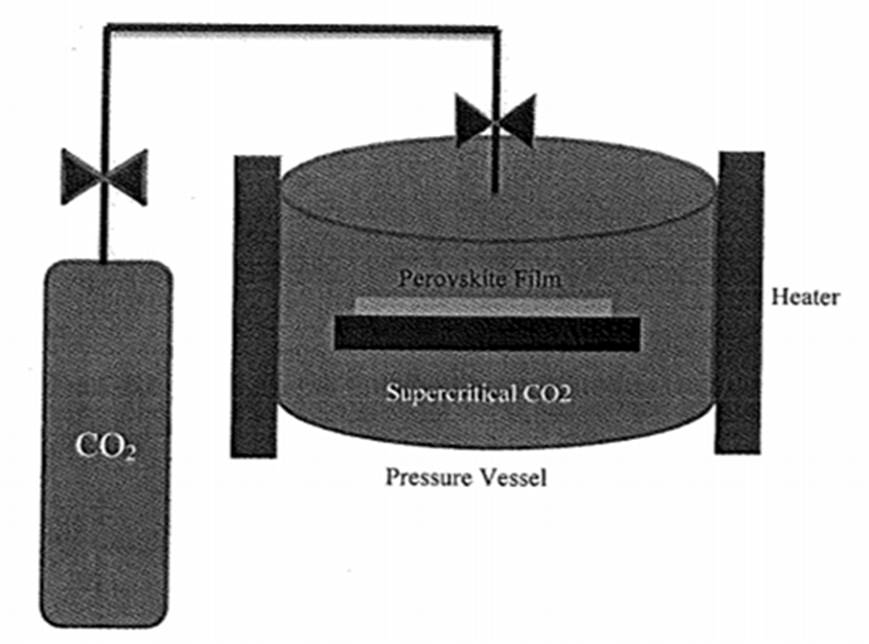

Inventors at Virginia Commonwealth University have successfully designed this novel method of using low annealing temperatures to create high-quality perovskite films. The films were able to be produced rapidly with annealing temperatures at lower than 40oC, which was possible in the presence of supercritical CO2. Without supercritical CO2, much higher annealing temperatures and annealing times were required to produce high-quality films. The supercritical CO2 acted as a mobilizer to significantly enhance the film crystallization rate at low temperatures and assisted in the removal of residual solvent from within the film. The films produced from this novel process have been characterized to show high-quality perovskite films with fewer visible defects.

Figure 1: Schematic diagram illustrating supercritical fluid pressure vessel for perovskite film processing.